Setting up a water-cooled turbocharger using an Electric Water Pump

Aussie Manufacturer Davies Craig Pty Ltd has been at the forefront of the automotive cooling business for almost 50 years!

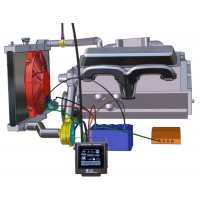

As well as developing Thermatic Electric Fans, 1996 the company turned its attention to engineering a unique rock-solid range of remote-mounted Electric Water Pumps, the company also supplies a broad range of compact Electric Booster Pumps. Some of these EBP models find their way into water-cooled turbocharger kits. There is also a growing trend to make use of the compact remote-mounted Electric Water Pumps with some inter-cooler and turbocharger applications!

There are many benefits to utilising a cooling system for a turbocharger and plumbing in an Electric Booster Pump (EBP®) or Electric Water Pump (EWP®). We all know heat, more specifically heat-soak can shorten engine, turbocharger, supercharger life and can destroy engine components. An appropriately plumbed cooling system for your turbocharger or supercharger will provide significant benefits to performance and well worth the effort required to install an adequate cooling system.

What does engine coolant really do?

Liquid cooling improves mechanical durability and extends the life of a turbocharger. Many turbochargers are designed to be sufficiently cooled by air. Other turbochargers are specifically designed and have built-in ports. Consequently, coolant and/or oil can be pumped through the main body. How can we tell the difference between an air/oil-cooled turbo and an oil/water-cooled turbo? If the turbocharger’s housing has threaded ports on either side, at 90° from the oil inlet/outlet flanges, it is probably a liquid-cooled model. To meet durability targets a turbocharger needs coolant running through its system. The major advantage of liquid cooling is coolant can be circulated after hot engine shut down. Heat generated in the turbo housing and exhaust manifold soaks into the centre section of the turbocharger. If coolant is not plumbed through correctly, the extreme heat can potentially destroy expensive turbocharger components.

How does liquid cooling work?

The process of a liquid cooled turbocharger can be orchestrated in two ways. During normal engine operation coolant flows through the turbocharger via the mechanical water pump. However, thermal siphoning can pull some coolant through the turbo’s centre housing or it can be pumped through properly routed coolant lines. Remember, a mechanical water pump stops when the engine is shut down which means coolant effectively stops circulating. This is where an auxiliary Davies Craig Electric Water Pump and/or Electric Booster Pump can be installed to assist with the component cooling process.

Heat built up in the centre housing is transferred to the coolant via conduction just like the cooling effect that occurs in a typical water-cooled engine through the built-in coolant capillaries. If coolant within a turbocharger flows freely after absorbing heat, it will circulate through the cooling system drawing colder coolant into the turbocharger along with it. In this way, the intense heat that has soaked back into the turbo after engine shutdown is removed from the turbo components and avoiding serious damage without assistance from the engine’s mechanical water pump.

How does liquid cooling extend turbo life?

Turbochargers generate an enormous amount of heat. Heat-soak is a huge factor with turbochargers, can ‘kill’ them fast and must be brought under control after engine shut-down. Heat originates in the exhaust system and during solid use, high exhaust temperatures unload enormous quantities of heat into the exhaust manifolds, turbine housing, and turbine wheel. While designed to manage extremely high temperatures some heat will want to naturally dissipate into the less heat tolerant centre housing and associated components as they are all inter linked. While the engine is operating and oil is flowing through the turbo’s bearing system, most of the heat generated may be cooled by the oil, preventing damage to the bearings and oil seals.

Obviously after engine is shut-down oil flow stops and so does the exhaust flow through the turbine. But intense heat is still evident in the exhaust manifold and turbine housing and it must be dissipated fast. The heat can only dissipate via conduction into the turbo’s centre and the exhaust pipe or radiate into the surrounding air under the hood. A small amount of heat will be transferred naturally to the surrounding air, but the majority will transfer from the turbo housing into the centre housing since the centre housing is at a lower temperature. Additionally, some of the heat will travel from the turbine wheel into the shaft and out towards the bearing system.

During the cool down phase heat creeps via heat soak into the turbo’s centre which lifts heat into the turbo’s centre. The temperatures of the centre housing, oil seal, bearings and any oil remaining in the turbo are all elevated above the normal operating temperatures, since the oil flow is no longer available to dissipate heat. Therefore, there is a greater risk for damage to the turbo during heat soak after engine shutdown.

Does your turbo have adequate cooling?

The above has given you a basic overview of the functionality of a liquid cooled turbocharger. We have also outlined that extreme heat is generated during operation and you can now understand the consequences of insufficient cooling. Turbocharger components can start to rapidly degrade at temperatures above 150°c (300°f) and risk permanent damage when exposed to these temperatures.

These temperatures may seem low when one examines exhaust gas temperatures which can reach 980°c (1800°f) and upwards in a high horsepower turbocharged engine. Examining liquid cooling specifically, the water jacket inside the centre of the turbocharger housing which is designed to keep all component temperatures below the limits to prevent premature failure. When coolant is not used or not plumbed correctly, component temperatures can easily go over limits and ultimately result in catastrophic turbo failure.

What is the right way to set up a water-cooled turbocharger?

Water-cooling a turbocharger does not need to be a complex project. The damaging effects of heat soak can be prevented from destroying the turbocharger through proper installation of the appropriate lines in the cooling system. The turbo’s coolant lines should be plumbed into the engine’s existing cooling system and can be teed off of the heater lines if they are still present in the vehicle and convenient. Engine coolant can be deployed without any concern. One can use 50/50 glycol/water mixture with most turbochargers. To receive the most benefit from water-cooling, the turbocharger’s centre housing should be rotated around the central axis (the shaft) so that the water ports are at an angle of approximately 20° from the horizontal. This is necessary to promote the thermal siphoning effect discussed earlier.

The coolant input (colder side, from the engine’s cooling system) should be plumbed into a port in the housing. The hotter output coolant returning to the engine’s cooling system should be plumbed into the higher port and allowed to travel “uphill” to the engine’s cooling system. Ensure there are no kinks in the return line. Select a port on the side of the turbocharger as an outlet. Coolant plumbing, colder coolant entering the low side, leading into the rotated centre housing and exiting the higher side, will reduce the formation of air pockets and allow unrestricted flow during hot engine shut down. The full benefits of a Davies Craig Electric Water Pump will be realised, and internal turbo temperatures will be minimized. The high temperatures in the centre housing can be reduced by as much as 50°c (90°f) when the centre housing is rotated to allow the hotter outlet coolant to exit from the higher port. With this brief explanation as to the benefits of adding an Electric Water Pump and circulating engine coolant through the body of any turbocharger during and after hot engine shut down should convince the sceptics of that water cooling is a critical element to the longevity of the unit’s components.

Several differing types of coolant lines can be utilised and there are several guidelines to follow. Be sure to use hoses or lines that are rated to at least as high as 120°c (250°f) or higher in some cases. The lines or hoses should be compatible with coolant and -AN fittings are recommended for simple, leak-free installation. Steel lines or flexible lines can be used but ensure they will cope with normal engine vibration. Most automotive engines are water-cooled, which means plumbing in a water-cooled turbocharger should be straightforward.

In summary, water-cooling is an important and straight forward requirement for turbochargers that are equipped with water ports. The consequences for overheating a water-cooled turbocharger can be terminal and destructive. The reward for a thoughtfully laid-out water-cooling system in good working order is a turbocharger that will be allowed to live the longest life possible under the extremely demanding conditions that it must withstand. Putting in some thought to examine appropriate coolant connections for your turbocharger, should reward you with excellent performance and longer life in your vehicle.