Electric Water Pumps

WHY SELECT AN ELECTRIC WATER PUMP?

The Mechanical Water Pump is one of the last mechanical components of the modern engine which has long been considered an inefficient device designed as an accessory on the earliest engines.

A mechanical belt driven water pump runs at the same speed as the engine regardless of how hot the engine is. Example: when travelling at high speeds down the freeway, the engine require less cooling as ram air is naturally cooling the engine however the engine speed is high as is the mechanical water pump thus providing excessive cooling whilst draining the engine of power. In heavy traffic with high ambient, the engine is idling or slow and so is the belt driven mechanical pump even though in this condition, extra coolant flow is required to cool the engine. So it works very efficiently when it’s not required and very inefficiently when it is required. The EWP® corrects this inherent flaw by delivery maximum cooling when it’s needed.

With an EWP® & Fan Digital Controller (12 & 24V) (PATENTS: USA 6425353, EU 1133624, AUS 756453), the speed of the pump is managed by the controller which varies the supply voltage to the pump and so varies the speed of the pump up or down hunting for a target temperature. When the engine reaches the target temperature, the controller locks on whilst constantly changing the Electric Water Pump speed to account for traffic and throttle conditions whilst all the while maintaining the target temperature independent of the engine speed. When the EWP® struggles to maintain your target temperature, the Digital Controller will operate the engine’s electric fan automatically once the engine has reached +3°C (+5.4°F) above the targeted / set temperature. Another significant benefit is that the Controller allows the EWP® & Fans to run on after ignition shutdown for either 3 minutes or -10°C (-14°F) of set / target temperature to eliminate heat soak.

Targeting the rapidly growing demand for cooling circulation pumps to maintain thermal stability in lithium-ion battery packs, the EWP® is offered as the optimum solution in terms of efficiency and cost. These pumps can be managed by a patented digital controller which modulates flow rates in response to selected temperatures.

Besides applications in the burgeoning electric & hybrid power systems, others in their sights are closed circuit condenser cooling and chiller a/c circulation pumps.

BENEFITS OF AN ELECTRIC WATER PUMP

The main benefit for using an EWP® is resolving an overheating engine issue & improved engine temperature control.

Other important improvement for your vehicle comes from the power the mechanical pump takes from the engine can be reclaimed with the use of an EWP® hence the fuel savings and increased horsepower. By removing the parasitic power losses of belt-driven water pumps, the EWP® may provide up to 10kw of extra power and additional fuel savings. The engine power used by the mechanical pump increases as the cube of its speed – so when the mechanical pump speed doubles from idle speed say; 600rpm to 1200 rpm, the power it takes increases by eight times. Then another eight times going to 2400 rpm, and so on up to maximum engine speed. It is this extra power and torque that is released by deleting the mechanical pump that provides the fuel savings that is estimated to be 3.5% to 10%.

Major European Manufacturers have implemented EWP’s® as standard issue on a number of their vehicles and our research shows that an EWP® uses 90% less energy than conventional systems, i.e.: the mechanical water pump. Other advantages will include lower emissions by virtue of faster engine warm up, better engine temperature management, eliminating engine heat soak and improved engine life.

Weight reduction is another benefit and key requirement of any automotive manufacturer seeking fuel savings and better performance. Our EWPs® weight between 900 grams up to 1,151 grams dependent on the EWP® model whilst a typical mechanical pump is in the range of 3kg up to 5kg. Not only is our EWP® considerably lighter, the universal flexible mounting around the engine bay provides options when seeking space within a crowded engine bay for other modifications.

SELECTION OF AN ELECTRIC WATER PUMP (EWP)

The size of your engine will help determine the appropriate EWP®

Davies, Craig’s range of patented Electric Water Pumps (EWP®) are available in flow rates from 90L/min (23.8 gal/min) up to 162L/min (42.8 gal/min) at 12v & 24volt and in Nylon66 / Alloy housings. Our EWP's are designed for universal fitment to compliment or replace a vehicle’s existing mechanical belt-driven water pump with simple, DIY installation.

| PRODUCT SELECTION GUIDE Electric Water Pump (EWP®) |

|||||||

| APPLICATION |

PUMP MODEL |

PUMP ONLY | PUMP KIT | PUMP COMBO | |||

| 12V | 24V | 12V | 24V | 12V | 24V | ||

| Engines up to 2.0L (Standard) |

EWP®80 | #8105 Nylon #8106 Flange #8109 Barb |

N/A | #8005 Nylon #8006 Flange #8009 Barb |

N/A | #8907 Nylon #8908 Flange #8919 Barb |

N/A |

| Engines up to 2.0L - 3.5L (Standard) |

EWP®115 | #8125 Nylon #8140 Alloy |

#8126 Nylon #8141 Alloy |

#8025 Nylon #8040 Alloy |

N/A | #8930 Nylon #8950 Alloy |

N/A |

| Engines up to 3.5L - 5.0L (Standard) |

EWP®140 | #8180 Alloy | #8181 Alloy | #8080 Alloy | N/A | #8990 Alloy | N/A |

| Engines 5.0L or greater (Standard) Modified Engines Supercharged/Turbo, Drag Racing, 4WD, Off Road, Drifting & Speedway |

EWP®150 | #8160 Sliver #8165 Black |

#8161 Silver | #8060 Silver #8065 Black |

#8061 Silver | #8970 Silver #8975 Black |

#8971 Silver |

| Intercooler (depending on capacity) |

EWP®115 | #8125 Nylon #8140 Alloy |

#8126 Nylon #8141 Alloy |

#8025 Nylon #8040 Alloy |

N/A | #8930 Nylon #8950 Alloy |

N/A |

| EWP®140 | #8180 Alloy | #8181 Alloy | #8080 Alloy | N/A | #8990 Alloy | N/A | |

| EWP®150 | #8160 Sliver #8165 Black |

#8161 Silver | #8060 Silver #8065 Black |

#8061 Silver | #8970 Silver #8975 Black |

#8971 Silver | |

EWP® INSTALLATION OPTIONS

AUXILIARY OR REPLACEMENT

An EWP®, can be used as an auxiliary pump in addition to the existing belt driven mechanical water pump to significantly improve cooling or as a replacement water pump to again improve cooling while at the same time increasing power to the drive wheels and saving fuel.

As an auxiliary pump, about 4 inches of the lower radiator hose is removed, and the EWP® is inserted in the gap. The EWP® is then wired through a thermal switch, sometimes the same switch which operates electric radiator fans, and both the fans and EWP® are connected directly to the battery. In this set up, when the engine reaches the thermal switch cut in temp, both the fans and the EWP® will turn on and cool the engine, to the switch off temperature. When the engine is hot and idling, the mechanical pump will be moving coolant at about 15 litres per minute, while the EWP®150 will kick in with up to an extra 162 litres per minute, and so dump a huge amount of heat. If you upgrade from the switch to our digital controller being wired to the battery, on hot shut down, the fans and EWP® will run for about half a minute and wash out heat which will protect the head gasket and other components from excessive heat damage.

DISABILING THE MECHANICAL WATER PUMP

- Leaving the mechanical water pump in place, install the EWP® into the bottom radiator hose and remove the manufacturer’s thermostat.

- You will need to bypass the water pump pulley by installing an appropriate length belt. This method makes for an easy installation.

- If running the pump continuously, remove the thermostat and drill two approx. 3mm (1/8") holes in the thermostat plate to allow some coolant circulation. Re-install ensuring that the thermostat housing is clean and a new gasket is used if required.

DISENGAGED MECHANICAL WATER PUMP (RECOMMENDED)

- Remove the mechanical water pump and remove the thermostat.

- Then remove the impeller from the mechanical pump shaft. Retain the mechanical water pump using the pump pulley as an idler to avoid re-routing the drive belt.

- Block any bypass passages and re-install the disengaged water pump ensuring that all gasket surfaces are clean and the new gaskets are properly fitted to prevent leaks.

- Install the EWP® into the bottom radiator hose..

REMOVE MECHANICAL WATER PUMP (IDEAL)

- Remove the mechanical water pump and thermostat from the engine.

- Install a Davies Craig EWP® Block Adapter or blanking plate (not supplied). Ensuring the gasket surfaces are clean and the appropriate gasket or sealant is used to prevent leaks.

- Install the EWP® into the bottom radiator hose. This method will require you to modify or replace the standard radiator hose.

- Install an appropriate length belt (not supplied) to drive the accessories.

In most cases EWP® will be adequately supported by the radiator hose. Where mounting is required, the EWP® must be soft mounted to protect against vibration. For the EWP115, EWP140 and EWP150 Part #8700 & #8710 Mounting kits are recommended.

EWP & CONTROLLER INSTALLATION DEMONSTRATION

- Davies, Craig recommends using Glycol 50% in water for all EWP® & EBP.

- Recommended viscosity range for all EWP & EBP: 100 mPa·s @ -30°C to 1 mPa·s @ 100°C

HOW TO MANAGE YOUR ELECTRIC WATER PUMP

- EWP used in conjunction with LCD EWP® Controller (PATENTS: USA 6425353, EU 1133624, AUS 756453)

The Digital Controller has a micro-processer which will run the EWP® at exactly the right flow rate maintaining the engine temperature you ‘set’. - EWP® used in conjunction with Thermal Switch Combine the EWP® with an adjustable Thermal Switch to add a cooling boost to an overheating mechanical pump cooling system.

- EWP® Continuous Running Wire the pump to the ignition for maximum cooling - suitable for race vehicles, very hot climates and chronically overheating engines.

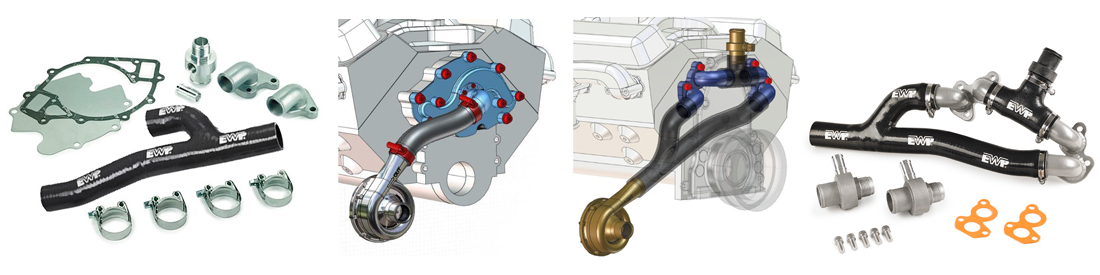

EWP BLOCK ADAPTER KITS

EWP® Block Adapter Kits are simply designed to complement the fitment of your EWP® Combo Kit.

If you’ve purchased an EWP® Combo Kit, then you will have an LCD EWP®/Fan Digital Controller with a built-in switch that will thermatically control the new electric Thermatic® Fan in unison with your new EWP®. Simple, easy-to-follow installation instructions are supplied to ensure the Davies, Craig EWP® Electric Water Pump Combo and EWP® Block-Adapter Kits are simply designed to complement the fitment of your EWP® Combo Kit.

EWP® Block Adapter Kits are assembled, mounted and perform in accordance with the product’s design.