Thermatic® Electric Fans

In 1971, belt-driven fans were the only option for automotive cooling. Searching for a more efficient method to cool and engine, Australian engineers Daryl Davies and Bill Craig created the first ever Thermatic® / Electric Fan.

Davies, Craig was formed to manufacture the new electric fans, and has since developed a comprehensive range in brushed and brushless versions covering most makes of vehicles. Our innovation in electric cooling has now become a standard feature on most of the world's new cars.

A Davies, Craig Fan is suitable for:

![]() Air conditioner condenser fans

Air conditioner condenser fans

![]() Transmission and engine Oil cooler fans

Transmission and engine Oil cooler fans

![]() Brushed and Brushless Motor Options

Brushed and Brushless Motor Options

Our fans provides constant air flow, increased fuel economy, better air conditioning performance, cooler engine running, and increased engine power. Our fans are fully reversible for mounting either side of the heat exchanger.

All Davies Craig fans are built in Upstream (Pusher) configuration from the factory.

For downstream applications, the fan blade must be removed and turned over and the wiring adjusted as per the instructions. Always check that the fan blade rotates in the direction shown by the arrows on the blade before making a permanent wiring connection and prior to fastening the unit to the radiator.

All Davies, Craig Thermatic® / Electric Fans are packaged with fan assembly (motor, fan blade, shroud and mounting feet). Fan fitting / mounting hardware sold separately. (See below)

Davies Craig backs the quality of its fans with an unprecedented 3 Year Manufacturer Warranty.

BRUSHLESS THERMATIC® ELECTRIC FANS

Offer outstanding performance for their size delivering increased air flow and 5 times the service life over the standard brushed models!

In our High Power range, they are also 25% thinner than its brushed High Power motor equivalent!

It provides, constant or variable air flow, increased fuel economy, improved air conditioning performance, cooler engine temperatures, low profile, high performance, increased engine power.

The IP68 rated motor with built in reversible motor rotation technology allows for either upstream (pusher) or downstream (puller) applications.

The flexibility of nine (9) different smart motor control modes; Full speed running, analogue speed control or pulse width modulation (PWM) speed control allowing for optimal control in any application.

Choosing a brushless fan over a brushed fan comes with several advantages:

- Efficiency:

- Brushless fans have higher efficiency, allowing for increased performance.

- Longevity:

- Without brushes to wear out, brushless fans can last significantly longer.

- Speed Control:

- Brushless fans allow for more precise speed control, making them versatile for various applications.

- Thermal Performance:

- They can handle higher temperatures and are more resistant to overheating, making them suitable for demanding environments.

- Ingress Protection:

- Brushless fans are IP68 Rated making them suitable for demanding environments.

- Compact Design:

- Brushless motors can be designed to be smaller and lighter, which is ideal for space-constrained applications.

Choosing a brushed fan over a brushless fan comes with several advantages:

- Cost:

- Brushed motors are typically less expensive, making them a more budget-friendly option.

- Availability:

- Brushed fans are widely available.

- Control:

- the straightforward on/off control of brushed fans can be an advantage, particularly in simpler systems.

THERMATIC® ELECTRIC FAN RANGE

UNIVERSAL FAN FITTING KIT

(SOLD SEPARATELY)

![]() SINGLE FAN MOUNTING HARDWARE KIT (12V) (1000)

SINGLE FAN MOUNTING HARDWARE KIT (12V) (1000)

![]() SINGLE FAN MOUNTING HARDWARE KIT (24V) (1001)

SINGLE FAN MOUNTING HARDWARE KIT (24V) (1001)

![]() DUAL FAN MOUNTING KIT - UNIVERSAL 12V (1002)

DUAL FAN MOUNTING KIT - UNIVERSAL 12V (1002)

![]() DUAL FAN MOUNTING KIT - UNIVERSAL 24V (1003)

DUAL FAN MOUNTING KIT - UNIVERSAL 24V (1003)

![]() FAN & TRANS OIL COOLER MOUNTING HARDWARE (UNIVERSAL) (0578)

FAN & TRANS OIL COOLER MOUNTING HARDWARE (UNIVERSAL) (0578)

![]() QUICK FIT KIT FOR FANS & TRANS OIL COOLER MOUNTING HARDWARE (UNIVERSAL) (0579)

QUICK FIT KIT FOR FANS & TRANS OIL COOLER MOUNTING HARDWARE (UNIVERSAL) (0579)

The Davies, Craig Universal Fan Fitting Kit includes all parts necessary for mounting and wiring any 12- and 24-volt electric fans

– all Davies, Craig Thermatic® Fans and other electric fan models.

WHAT SIZE THERMATIC® / ELECTRIC FAN DO I NEED?

Davies Craig has made this process extremely easy –

A). Jump onto our website, https://daviescraig.com.au/fan-fitments

B). Click onto “Fan Selection Guide” in the grey banner on the top of home page. C). Place your vehicle make and model in the spaces provided or measure your radiator core dimensions (width, height and depth, (being the distance from the front of the engine to back of the radiator core).

The “Fan Selection Guide” will simply give you the appropriate fan options for your radiator to make a safe and correct choice.

If your car make is not listed in our Fan Selection Guide or the Model Selection Guide (see the Davies, Craig website, www.daviescraig.com.au/catalogues) we suggest the following:

- Measure your radiator core dimensions (width, depth and clearance - refer diagram below) and refer to “Fan Models” to check which fan/s will fit your core.

- Davies Craig Thermatic® Fans are reversible which means they can be mounted upstream or downstream, as illustrated below.

- In general, one large fan will have better airflow than two smaller fans. Where radiator is rectangular there may be no choice but to fit two smaller fans; choose the largest that can be accommodated in space available. The fan can also be mounted offset from centre to clear engine components when mounted in the downstream position.

Note: Fans should not be fitted on opposite sides of radiator core unless these are offset such that the airflow of one is not interfering with the airflow of the other. - If you require advice, please contact Davies, Craig for assistance.

Fan Mounting Direction

BENEFITS OF A DAVIES CRAIG THERMATIC® / ELECTRIC FAN

As a primary cooling source electric fans provide:

- Unprecedented 3 Year Warranty

- Economical replacement for failed original equipment.

- 5-10% increase in engine power and fuel saving when replacing fan clutch and fan assemblies

- Reversible blades for pusher (upstream) or puller (downstream) applications

- Compatibility with all electric fan controls

- Coverage for a wide variety of applications

As an add-on cooling source electric fans provide:

- Constant air flow regardless of vehicle speed constant air flow across the condenser

- Increased air conditioning performance due to constant air flow across the condenser

- With the conversion from R12 to R-134A refrigerant there is a need for additional condenser cooling to ensure the overall improved efficiency of the cooling system

- Increased fuel economy All of our electric fans kits are packaged complete with instructions and mounting hardware for quick and easy installation

CAUSES OF OVERHEATING IN ORDER OF LIKELIHOOD

- Fan facing wrong direction.

- Fan rotating wrong direction.

- Fan wired to coil or alternator (only 8 Volts.)

- No condenser fan.

- Temperature gauge faulty - disagrees with thermometer in radiator.

- Towing a heavy caravan.

- Inadequate kit fitted.

- Oil cooler obstructing ram air.

- Insect screen obstructing ram air.

- Driving lights obstructing ram air.

- Number plate obstructing race air.

- Battery not up to 13 Volts.

- Insufficient water in radiator.

- Radiator need5.cleaning.

- Radiator cap faulty allowing water to boil at 100°C.

- Thermostat faulty.

- Electric motor faulty.

- Fan not in hot corner of radiator.

- Engine out of tune or idling too fast.

FAN SET UP: UPSTREAM (PUSHER) OR DOWNSTREAM (PULLER)?

Davies Craig Electric Thermatic Fans can be simply set up to either push air through the radiator or pull air through it. A upstream (pusher) fan sits flush up to the front of the radiator core. A downstream (puller) fan on the other hand sits right behind and flush with the rear of the radiator core. The downstream puller fan pulls air through the radiator and has less impact on airflow at high speeds than a upstream pusher fan since it is behind the radiator.

A downstream puller fan is slightly more efficient than a upstream pusher fan. A puller draws the air in at any angle and around obstacles like a vacuum, pulling the hot air from the radiator at a constant wind force, known as CFM, Cubic Feet per Minute. A upstream pusher fan will push air through the radiator and, on occasions this may cause some bounce and as a consequence may lose some of its flow. When pushing air the fan will commence with a certain CFM but then as the air hit the fins and tubes and creates turbulence you may lose some air flow. Also, once the vehicle reaches around 60 kph the stronger ram air takes over and the electric fans become superfluous. Hence an uninhibited frontal radiator area offers greater cooling efficiencies at highway speeds.

Now, what is vital is the size and indeed the strength (wind velocity known as CFM) of an Electric Fan. If space is an issue between the rear of the radiator and front of the engine then install the largest Electric Fan possible at the front of the radiator.

The more air flow, being pushed or pulled through a radiator, which is usually related to the size (diameter) of the electric fan and the strength of the electric motor, the better. Hot air extracted from a radiator, known as heat exchange, either being pushed or pulled should exit the rear of the engine bay essentially uninhibited/unobstructed.

Finally, Davies Craig Thermatic Electric Fans are manufactured in Australia and offer reverse polarity which means they can be mounted as either a ‘pusher/upstream fan’ or ‘puller/downstream fan’ by simply reversing the wiring and turning the blade over on the shaft. All Davies Craig Electric Thermatic Fans are accompanied by a 2-year unconditional warranty.

Straight vs. Curved Fan Blades - Dispelling the Myth!

The relative merits and technology of curved vs. straight fan blades, has been debated for some time. Davies, Craig conducted an extensive research program to formulate the design of fans in which several design types including curved blades with and without a ring were considered. Curved blades generated less noise but at the expense of a significant loss in performance caused by the fact that curved blades stall at a lower static pressure than straight blades. If a fan moves less air, then, simply you can expect less noise. As shown in the performance curves below, Davies, Craig Thermatic Fan outperforms its competitor across the full pressure range:

Noise Control: Most fan noise is generated from a blade passing a shroud strut. The noise level is higher when the whole length of a blade overlaps/passes a shroud strut and if all the blades pass all the struts of a shroud at the same time, NOISE IS AT ITS WORST. Some manufacturers have chosen to curve the blades and keep the struts straight. Since this approach significantly affects performance, Davies, Craig has proven it's best to adopt the reverse approach of having straight blades and curving the struts.

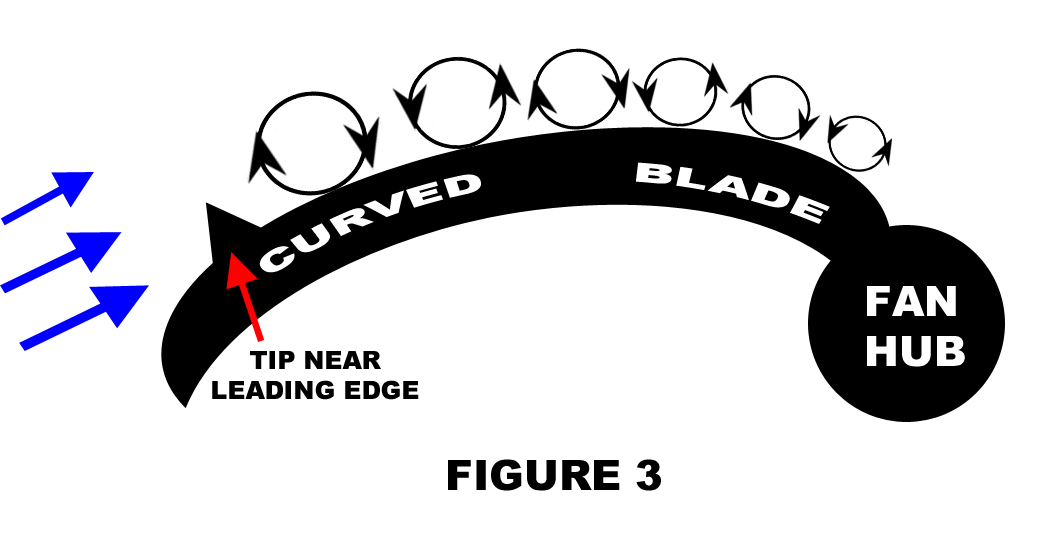

Our investigations also found that when air flowed in layers (laminar flow), it breaks up into counter rotating airflow vortices (whirlwinds): Figure 2

These vortices consume energy and therefore reduce the airflow. It was found that by inserting triangular protrusions near the leading edge of the blade, the air is tripped into going into vortices earlier but they were much smaller and removed much less energy therefore making the blade more efficient (Figure 3).

The idea of a ring around the blade tips was also researched and rejected since the performance suffered due to the increased energy required to propel the blade with the extra weight at the tips. While the purpose of a ring is to reduce losses from air passing from the high-pressure side of the blade to the low-pressure side as shown, Davies, Craig managed to achieve this by adding winglets to the blade tips without energy loss.

When all aspects of blade design are considered, straight blades with tips, winglets and the correct shroud is the optimum, test-proven combination for efficient fan operation.