History and form on Davies Craig’s side when it comes to assisting air conditioning systems! Who w

Who would have thought, that back in the ‘60’s two young Aussies Daryl Davies and Bill Craig would carve out a niche in Australian automotive aftermarket history with their innovative work developing Australian automotive and air conditioning electric fans? From very humble beginnings Davies and Craig, both of whom were qualified commercial airline pilots formed Davies, Craig Pty Ltd almost 50 years ago. This Australian owned and operated company commenced as a manufacturer in the automotive and air-conditioning condenser cooling fan industry sectors producing a range of innovative Thermatic® Electric Fans.

While much has been written about the utilization of Davies Craig’s Thermatic® Electric Fans as cooling fans fastened to the front or back of literally thousands of radiators around the world very little is known about the extensive use of Thermatic® Electric Fans in the air conditioning industry. The role played in an air conditioning system by the electric fan is vital and must offer adequate air flow to complement the heat exchange provided by the condenser which, combined with an adequate compressor and evaporator should give you cool, refreshing in the vehicle’s driver/passenger compartment.

Let us examine the air conditioning system and put forward some questions relating to the condenser, the electric fan, which, along with the evaporative cooler and compressor are the most vital A/C components.

Firstly, does the size of the condenser matter? The size of the condenser is determined by the core size of the radiator. The larger the better; fill as much of the radiator core size as possible. The evaporator absorbs the heat from inside the vehicle, and the condenser dissipates the heat. One cannot oversize a typical condenser.

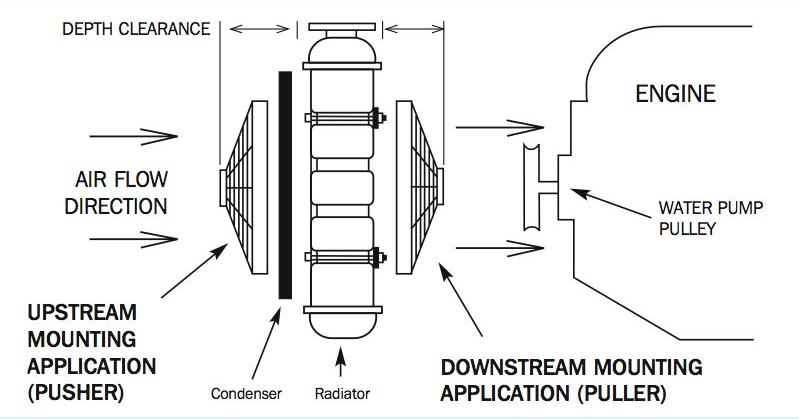

Secondly, what is the general affirmation, mechanical or electric fans with air conditioning? The key is air flow, and a large electric fan or twin fans will deliver a high CFM ft3/min. Be careful when selecting an electric fan as the primary cooling fan-many just do not have the air flow capacity. One should examine the use of either Davies Craig Thermatic® Electric Fans, 14” high performance or 16” Electric Fan, mounted flush with the radiator core and set up as a ‘puller’. You will require a minimum of 2100 CFM ft3/min. of airflow. Depending on the vehicle, if you can also install a ‘pusher’ fan as a secondary fan on the condenser core, this will increase the air-conditioning performance at low speeds or idle (traffic).

Thirdly, what determines the size of an air conditioner evaporator? The amount of available space is the key factor here. You install the largest unit possible that will fit into the available space. Several factors also come into play. First and foremost is the size of the interior you are trying to cool. The second factor would be the amount of physical space behind the dash in some cases. Keep in mind that when the system is on high and working to its maximum capacity-say, on a 40°c day, it is easier to turn the A/C down than to turn it up!

Fourthly, are there any suggested engine/cooling system modifications necessary when adding air conditioning? You need to ensure you have a high-performance, high CFM ft3/min. Davies Craig Thermatic® Electric Fans, and a high volume flowing mechanical water pump or install a suitable Davies Craig Electric Water Pump and finally, at least a double row aluminium radiator. Should you select the Davies Craig Electric Water Pump be sure to opt for the Combo which offers the LCD EWP/Fan Controller, the electric adjustable thermostat. We strongly recommend the addition of a safety switch, which allows A/C system pressure to engage the electric fan/s in conjunction with and independent from engine temperature.

Do you recommend mechanical or electric fans? Electric fans are preferred because sufficient airflow must be maintained at idling or low ground speeds. Airflow supplied by a mechanical fan changes with engine rpm and can be insufficient at low-engine rpm and absorbs horsepower. With most cars and light trucks, the installation of a Davies Craig Thermatic Electric Fan/s is a great choice to free up horsepower and decrease fuel consumption. If the vehicle is to be used under "extreme" conditions, such as towing, high powered electric fans are essential. Keep in mind that the only time a fan should be necessary is when the car is at idle, low speed or standing still and an automatic Thermatic Switch should be installed. Today's Davies Craig Thermatic Electric Fans are producing more CFM ft3/min. than ever, and 2,000 CFM ft3/min. are common.

Do you recommend internal or external automatic transmission coolers? Most vehicles today are fitted with some form of transmission oil cooler. Usually the manufacturer has built in a cooler under the radiator the transmission oil cooler under the radiator module creates additional heat inside the radiator. These can prove to be inadequate given you are circulating hot transmission fluid under an already very warm radiator or installed a small core in front of the radiator. These may be adequate for normal driving conditions. An external or auxiliary Davies Craig Transmission Oil Cooler keeps unnecessary heat out of the radiator and is essential for towing as additional heat will be generated and must be compensated if you are to maintain acceptable transmission life.

What interior modifications do you recommend when adding air conditioning (tinted windows, insulation, etc.)? The single most important factor in improving the efficiency of a climate-control system is how well the vehicle is sealed and insulated. You must keep the engine heat and outside heat out of the interior of the vehicle. Keep one thing in mind-air-conditioning systems do not make cold air; they remove the heat that is in the air, Tinted windows help reflect the hot sun, assisting the air conditioner cool the vehicle more efficiently. Proper weatherstrip and door/glass seals will also help isolate the interior and lessen the load on the A/C system.

What are the most common air-conditioning installation errors? Not preparing for air conditioning in the planning stages, lack of insulation, and not allowing for appropriate space. The evaporator requires a certain amount of space and can be remotely mounted if necessary. Overcharging or undercharging the A/C system. Condensers must be mounted with the manifold tanks in a vertical orientation. Ensure you seek advice from a fully qualified specialist to assist you with this process. Under-sizing the evaporator to the vehicle-especially on finished vehicles can be an issue. Customers constantly call stating they only have so much space left, so they'll take whatever will fit. They don't like to hear that they really need to move other components around to get an evaporator large enough to do the job.

Southern Air

The biggest error is the incorrect installation of the water valve. Many people think that the water flow is from the water pump, but it's from the intake manifold or my favorite place, the cylinder head. If you use the port between numbers 7 and 5 on the head, you have one quarter of the heater hose to run and this is the hose you install the water valve on. Our electric four-way valve helps solve this problem.

The second biggest mistake is the over- or undercharging of the system.

Vintage Air

The most common installation error we deal with is improper system service.Modern 134a systems must be properly evacuated and charged to operate at maximum efficiency. Failure to properly charge a system will result in improper operating pressures, unsatisfactory duct temperature, and overall poor system performance.

The second is failure to properly install and insert the thermostat capillary tube. This results in improper coil temperature sensing by the thermostat, which leads to coil freeze-up, reduced airflow from the unit, and poor duct temperature.

Finally,

Maintaining adequate air flow at various speeds is essential and can be complex. Scoops, lips, deflectors and recessed panels can be used to improve air flow when the frontal area of a vehicle is less than ideal.

To function efficiently, the air stream on the front side of the radiator/needs to be higher than the air stream behind it. High pressure forces ram-air through the core

The next issue that requires serious attention is the fan. Engine-driven fans must have a circular shroud to be fully effective, says Davies, Craig, which states the blades should have no more than one inch in clearance to the shroud. Some mechanical fans can reach a blade stall at high RPM, causing a ‘wall’ which prevents air from passing through it. As such, Davies, Craig says the installation of a temperature-controlled, radiator mounted electric fan, in the majority of cases, as a replacement, is far more efficient.

For this reason, consideration should be given to vehicle’s use for both low speed cruising and higher speed operation to ensure the effective channeling of air to the radiator while operating in both circumstances.

Nearly all modern-day vehicles have an electric, temperature-controlled fan as standard equipment at the rear of the radiator and all modern electric fans have a standard circular shroud to maximise efficiency, explains Davies, Craig.

Pay attention the fan’s motor power (watts) and the published (CFM, Cubic ft3/min), the specific fan produces, usually the larger the electric fan the higher the CFM. Davies Craig publishes all the specifications and dimensions on its website, www.daviescraig.com.au

Some electric fans may be enclosed in a metal or nylon cowling (referred to as a shroud) which is designed to be rear radiator mounted only. Speeds of 60kmh or under, electric fans are most effective due to their total operating independence from engine revs.

Ram air intake driving above 60kmh, a fan is not as necessary, says Davies, Craig, which states the use of a cowling can be problematic as encompassing the entire rear radiator core can inhibit air flow at speed. If there is a build-up of air pressure in the fan cowling or engine compartment, air flow across the radiator can stall, causing higher engine temperatures.

For example, Davies, Craig notes that an electric fan and cowling that covers the entire core should have "trap doors", usually made of silicone, rubber or nylon, installed to assist with cooling efficiency. When cruising at low speed these trap doors will stay closed to prevent bypass. While at speed, the doors will open to allow more air flow and prevent the cowling from damming the air.

Since the engine compartment must be able to maintain pressure differential as a vehicle’s speed increases, many original equipment manufacturers install air dams or other wind deflector devices to increase the pressure at the face of the radiator and block the air from passing under the car.

Davies, Craig states an electric fan’s operation is not ‘complete’ without an appropriate Digital Thermatic Switch. Using either a Davies Craig Thermatic Switch or LCD EWP/Fan Controller will activate the electric fan/s at set/targeted temperatures.